Recording and Display Systems

Roll Measurements and Tolerances by Application

Recording and Display Systems.

Fig. 11-A. Portable recording system records a measurement for downloading onto a PC system.

In both cases, two gages and an encoder for distance are wired to an interface board in a PC system for recording, analyzing, displaying, printing, and storing of measurement reports. The most sophisticated RollTrack® software features include:

Restore/backup roll reports from/to hard drive to/from diskette.

Store and edit roll information by roll numbers.

A page for additional roll data for each roll.

Upload reports from a hand-held computer.

Save, edit, delete roll measurement reports.

Warning if the graph screen is escaped without saving a report.

Change scale, tolerances, and # of stations before or after saving a report.

Taper correction; A report can be redrawn without a taper error.

'Examine graph' for readings and locations between the stations.

Non-centered (start from zero) or centered graphs.

Low, standard or high resolution.

Inches/mm change.

Change wheel diameter or encoder line count in options if resp.hardware is replaced.

Data fields for customizing the report form quickly any time. In addition to continuous graphs, the gage readings can be recorded statically at each station when greater accuracies are required.

The PC system may be used to plot existing reports by entering the station values via the keyboard.

Black and white or color printing.

Measurement results can be sent to roll grinder controls for automatic correction in finish grinding.

The RollTrack® system uses an off-the-self IBM AT 386 or higher, or compatible PC. The benefits of the PC based recording systems are that the measurement reports are recorded and plotted automatically reducing possibilities for human errors. The reports include roll and measurement data on a single form, so there is no need for hand written report generation.

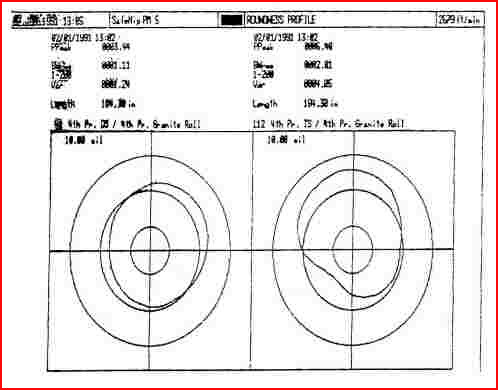

Fig. 11-B. Computer display sample with a Profile graph, Roundness graph, and two T.I.R. graphs on the same display screen.

Correlation to Condition Monitoring Systems.

Because of the continuous concentricity, roundness and profile graph capabilities with the advanced PC measuring systems, the results can be correlated to the reports from the in-line condition monitoring systems in paper machines. A condition monitoring system gives a new window through which the paper machine can be viewed. E.g. the Measurex SafeControl system is broken into four main areas: SafeCondition, SafePulsation, SafeQuality, and SafeNip. SafeCondition is bearing and gear analysis; afePulsation analyses wet end operations; SafeQuality looks at basis weight, moisture, and caliper variations in the machine directions; SafeNip looks at displacement vibration in machine nips.

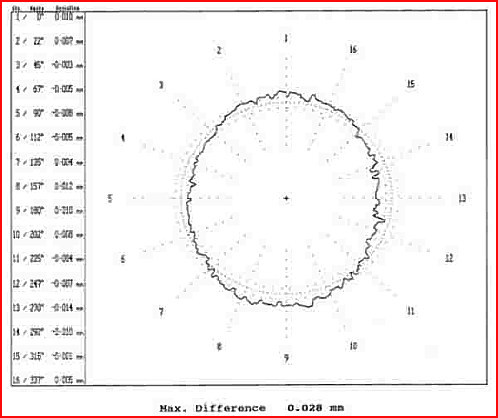

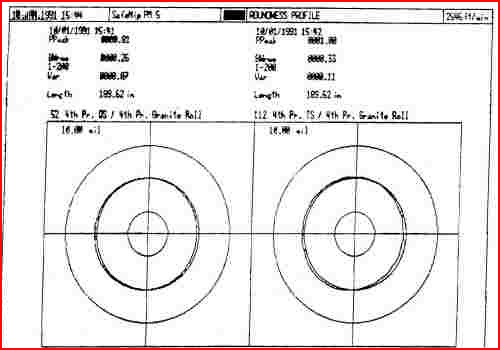

Since coming on-line the monitoring system has provided evidence in many areas of the paper machine at a paper mill. Recently, a granite roll was placed in the press section of No. 5 Paper Machine of the mill. The roll immediately showed high vibration levels caused by the roll being out-of-round which was confirmed by measuring the roll with the RollTrack® roll caliper mounted on the Farrel two wheel roll grinder and then by comparing the roundness measurements to the SafeNip roundness profiles. The roundness problem was linked back to the roll grinding procedure and equipment. The granite roll was removed less than two months after being placed in the press.

Roll life, felt life, paper quality, and equipment condition can be monitored by the on-line process monitoring system. With a link between the paper makers and the preventative maintenance group, many problems on the paper machine can be avoided.

Fig. 12. In-line Roundness Profiles from the SafeControl system.

Fig. 13. Roundness report from the RollTrack® system. The same granite roll as Fig. 12, dia. 62" x 384" face length.

Fig. 12-A. In-line Roundness Profiles of the same roll after the roll had been reground to the specifications.

SafeControl is a trademark of Measurex Corporation.

References: JASKE, E.J. Roll Measurement and Tolerances, Pulp and Paper Canada 90(2):T73-77 (Feb. 1989)