Measuring Equipment

Roll Measurements and Tolerances by Application

Measuring Equipment

A variety of equipment is needed to measure the surface characteristics, geometry and rotation of a roll Plastometers, durometers, schleroscopes, profilometers, and semiconductor thermometers are needed to measure the roll surface

characteristics.

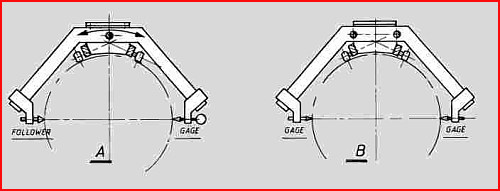

Steel tape measures (Pi-Tape) scaled for diameters, and micro-meters are used for diameter and taper measurements. Analog or digital dial indicators with magnetic bases or other holders are used to check T.I.R. on the roll grinder, and the paper achine. They also are used to measure roll alignment, journals, etc. Manual saddle-type roll calipers with swinging arms, and follower on one side and electronic gage or dial indicator on the other side, are the most common devices for measuring roll diameter changes from one checking station to the next one. The results are used to check straight profile, crown and taper. A manual system is most versatile as it can be used to check rolls on a roll grinder, on the floor, or in the paper machine. An encoder with a wheel against the roll can be installed on the saddle, and portable computer records measurements from the gage by distance from the encoder and plots the results into a continuous graph. Reports can be printed out or uploaded on a PC system for permanent storing, analyzing, editing, and printing later.

Repeatability of 0,001 mm (.00004 in) can achieved with the best saddle mikes. A fixed arm saddle mike with gages on both sides, can be used for even more accurate measurements.

Fig. 9. Saddle-type roll calipers. A. Swing arms. B. Fixed Arms.

Manual saddle mikes are most accurate if the saddle is kept level while traversing across the roll face, the contacts are exactly on the centerline of the roll, the caliper design is rigid and torsionless, and the wheels are rotating concentric within a tight tolerance to each other.

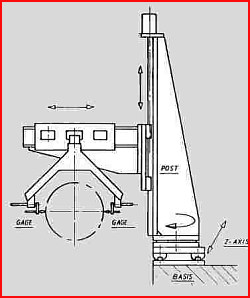

The two gage principle is the most accurate for machine mounted roll calipers. A post with an arm over a roll is mounted on the carriage of a single wheel roll grinder. C-frames for different roll diameter sizes are mounted on the arm. Since two gages are used, a roundness measurement is possible in addition to profile, crown and concentricity.

Fig. 10. Machine mounted roll caliper with post/arm and C-frames.

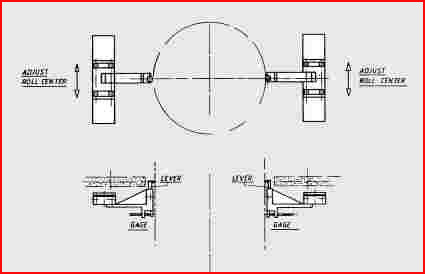

Special brackets are used with the two-wheel roll grinders taking advantage of the wheel heads as gage holders in place of a post/arm design with C-frames. As the wheel heads can be held at a fixed (adjustable) distance from each other, the two gage principle can be applied.

Fig. 11. Machine Mounted Model for Two Wheel Roll Grinders.