Roll Motion

Roll Roundness and Motion Measurement with Motion Control

FMT Equipment has developed of a new roundness measurement method of large rolls rotating in their own bearings in a roll grinding machine. Between mechanical designs and mathematical procedures, run-out can be eliminated from a measurement. And even more importantly, periodic motion from the bearing clearance or other external sources can be measured and separated from the roundness measurement.

1. The above animation shows how movement of the roll center causes an oval grind shape in this case.

2. Once the motion is ground to the roll surface as oval shape and the roll keeps moving periodically, then zero deviation is measured on the wheel side and double the error on the back side.

3. Unless the motion is compensated by moving the wheel head, or the movement is taken out in bearings, the roll cannot be ground round accurately.

Circular Roll Measurement Principle

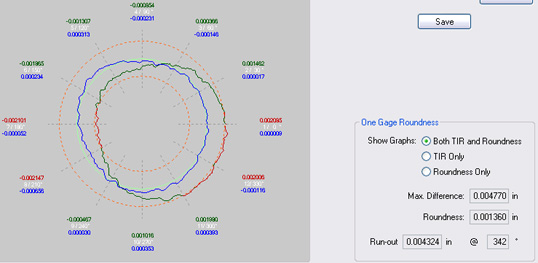

A single probe is required to measure run-out and roundness of a cylinder if the center of rotation is fixed. The run-out and roundness can be separated mathematically. However, there usually is some motion when grinding a large roll in its bearings. or supported on roll journals on babbits If a disturbance is periodic and matches the roll rotational frequency, then this disturbance is ground into the roll surface. If the measuring probe is located on the wheel side, it does not record this disturbance. Therefore, two probes are required to measure Runout and Roundness of a roll with periodic motion.

TIR/Roundness Measurement Report: Max. Difference is Total Indicator Reading which includes run-out and out-of-roundness. Roundness is the value after removing run-out from the measurement. Run-out is eccentric rotation of the roll. Angle is the direction of eccentricity.

The Company paper by FMT President Juhani Jaske and Consultant Dominic D’Amato, was covered in the article entitled “Roll Grinding – One Key to Proper Roll Maintenance” in the April 2005 issue of Paper Asia magazine.

Please send us e-mail to request a copy of the paper.