Servo Control

Viewing video requires access to YouTube.

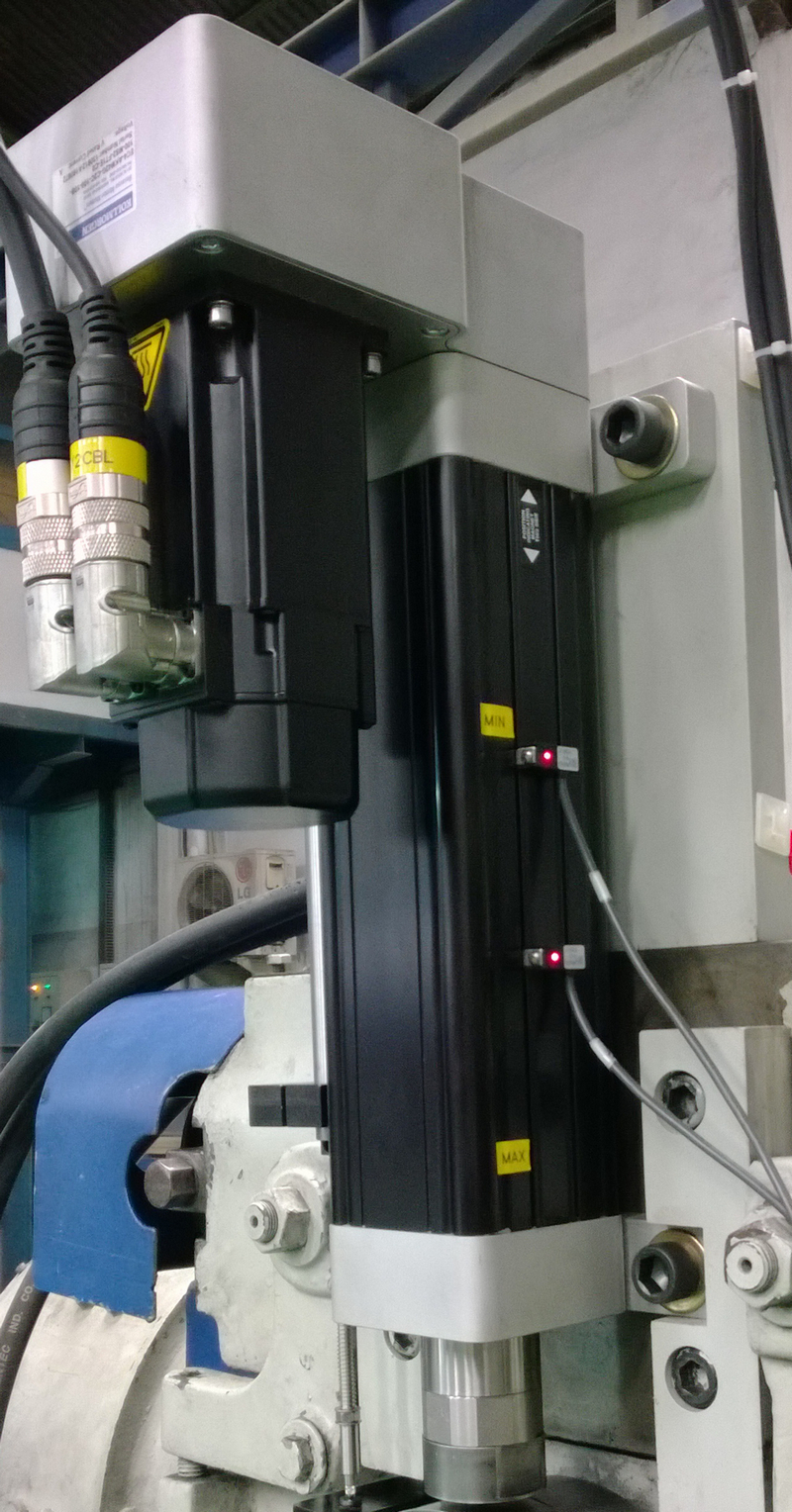

The RollTrack® servo system controls the tilt infeed of a wheelhead to grind a roll with straight or crown shape, and to compensate the paths of consequent grinding passes from a roll measurement.

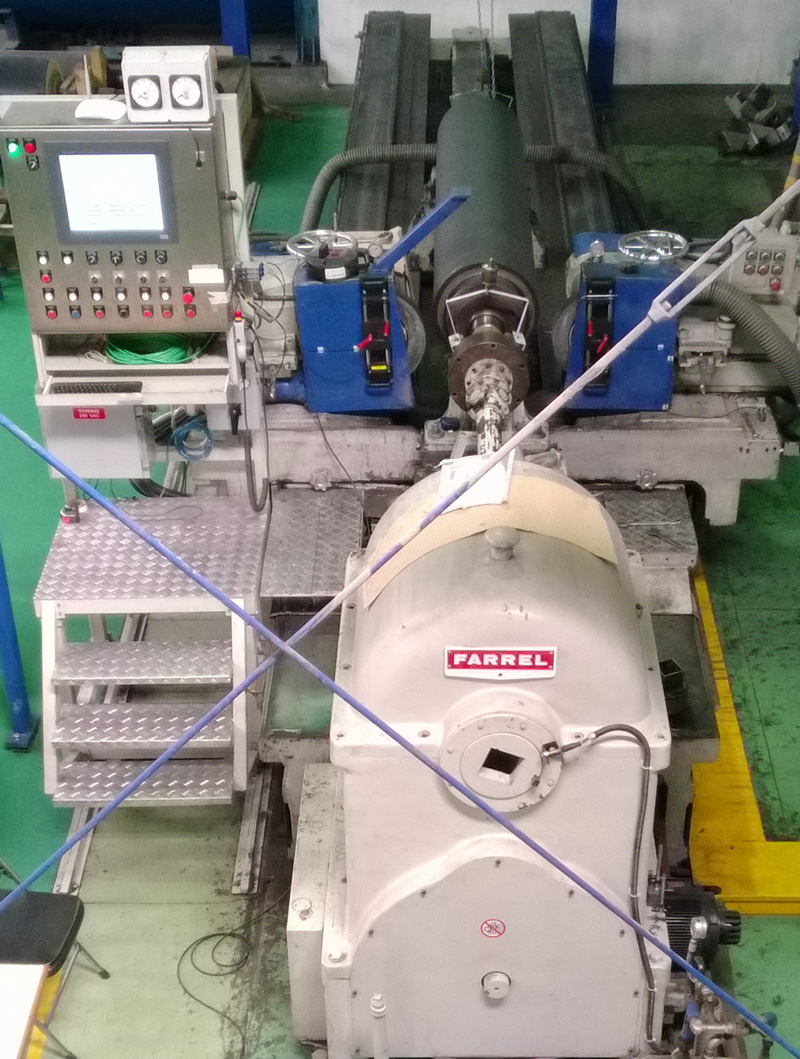

The FMT RollTrack® servo control system installed on the left side of the above Farrel two-wheel roll grinder.

The RollTrack® Grinder option is an additional option to the RollTrack® measuring program including features:

- Setup for grinding.

- Set roll grinding parameters by existing controls (roll and wheel speeds, traverse), or RollTrack® option.

- Open the RollTrack® Grinder menu and select Grind Profile (straight) or Crown.

- Set total crown, angle, and length.

- Capability for off center crown or secondary crown targets.

- Set continuous infeed as needed.

- Set end infeed as needed.

- Set taper correction as needed.

- Capability to dub roll ends (grind taper).

- The servo infeed is activated by the carriage position.

- RollTrack® computes the current crown height at each station.

- RollTrack® checks the reference gauge and moves the servo in or out to make the wheelhead match target height at the location.

- If an intermediate measurement is done on a roll, the measuring results can be applied to the control program to correct the grinding wheel path accordingly.

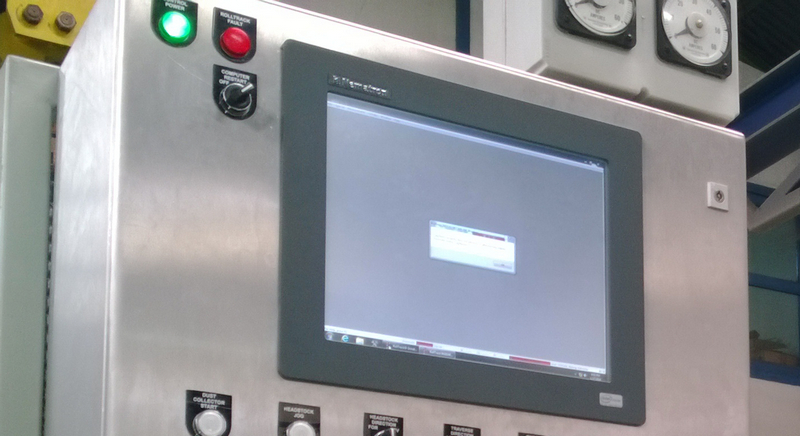

RollTrack® touchscreen is added to the main control panel.