Machine Mounted 1

The measuring device records, displays and provides a hard copy of the measurement in a form of a graph representing continuous measurement over the length or circumference of the roll. The results can be sent to computerized or CNC controls to modify a bed correction curve automatically.

The measurement graph displays the nominal or base measurement parameter (zero-line, cosine crown, or compound crown target) and tolerances. The system provides reports on the following measurement modes:

- Two point straight profile measurement

- Two point crown and compound crown measurements

- One point concentricity/eccentricity measurements at 3 and 9 o'clock positions

- One point Roundness measurement

- Two point run-out, roundness and motion measurements

- Special measurements such as sag, roll alignment, straightness of ways and T.I.R. in other positions are possible using standard modes. Resolution of the measuring system is selectable .0005", .0001",.00002", 0,01 mm, 0,001 mm or 0,0005 mm. A special high resolution model is available at .000004" (0,0001 mm) resolution.The RollTrack® recording system provides report display and hard copy capabilities. The graph is displayed while measuring (profile and crown) or immediately after (T.I.R. and roundness) a measuring pass. The reports also include manually entered or previously saved roll data. There is adequate memory space for saving the reports on a hard disk, up to 1000 roll numbers and 1000 reports on each roll.

-

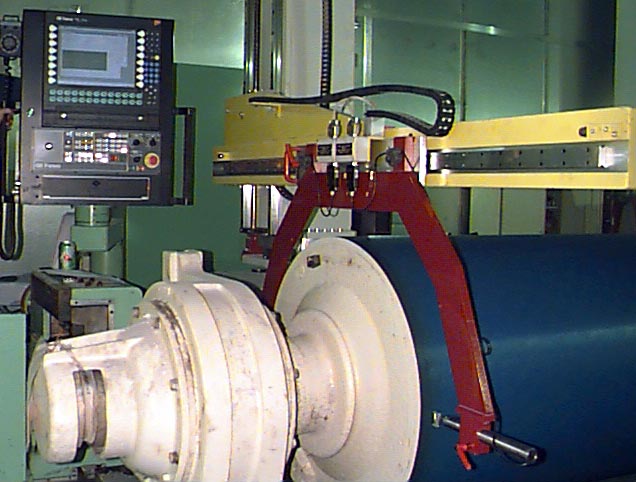

Picture below: This roll caliper with FMT RollTrack® is integrated into the GE Fanuc CNC-controls by Abbott Machine.

-

Picture below: A roll caliper with FMT RollTrack® in process gauging.

-